High-Gloss Doors With Stainless Steel Inlay

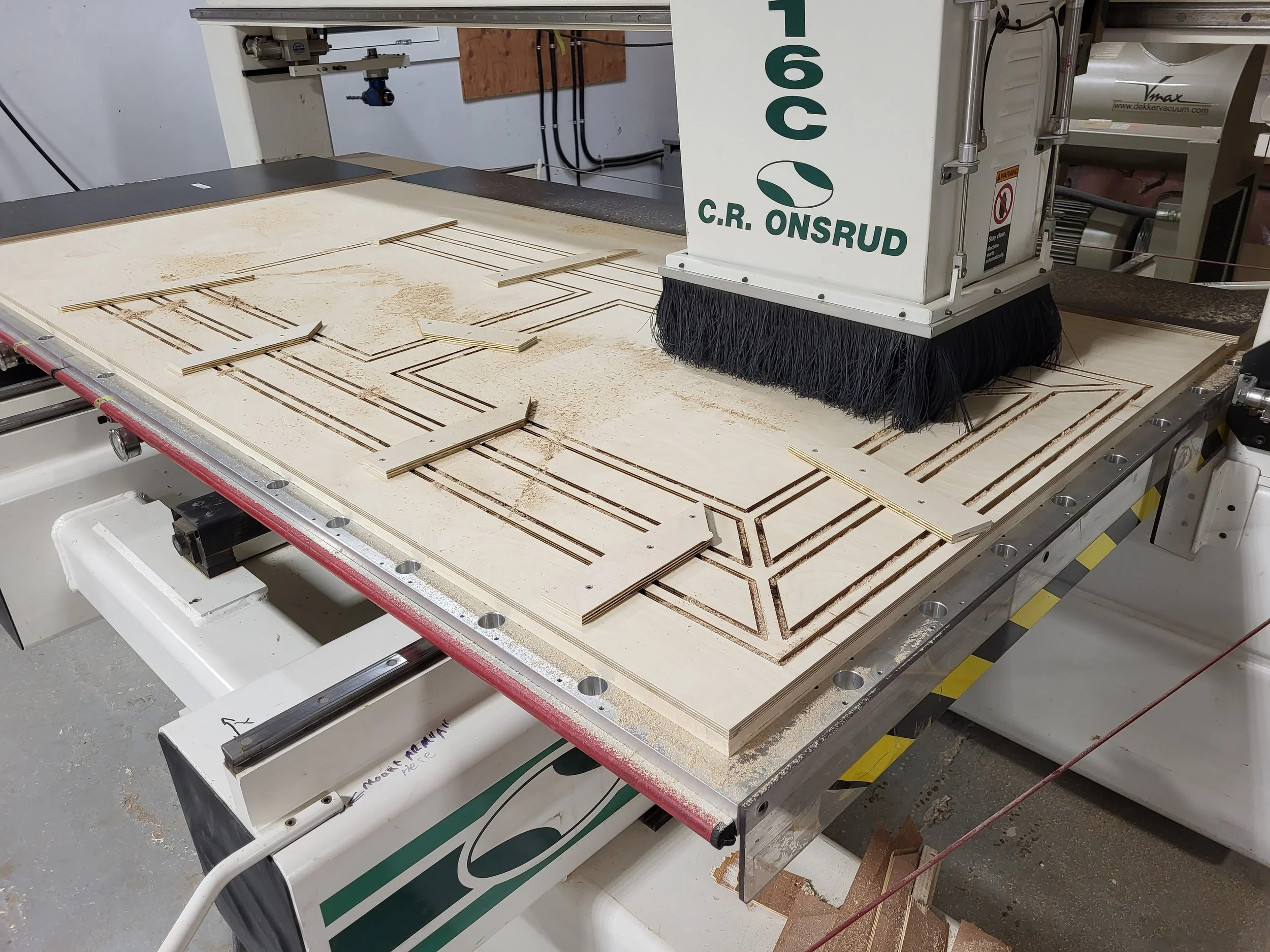

These doors were made for Rare Bar at the Encore casino in Boston, USA. I was tasked with programming and machining these doors, as part of the team who manufactured them at Bar None Design.

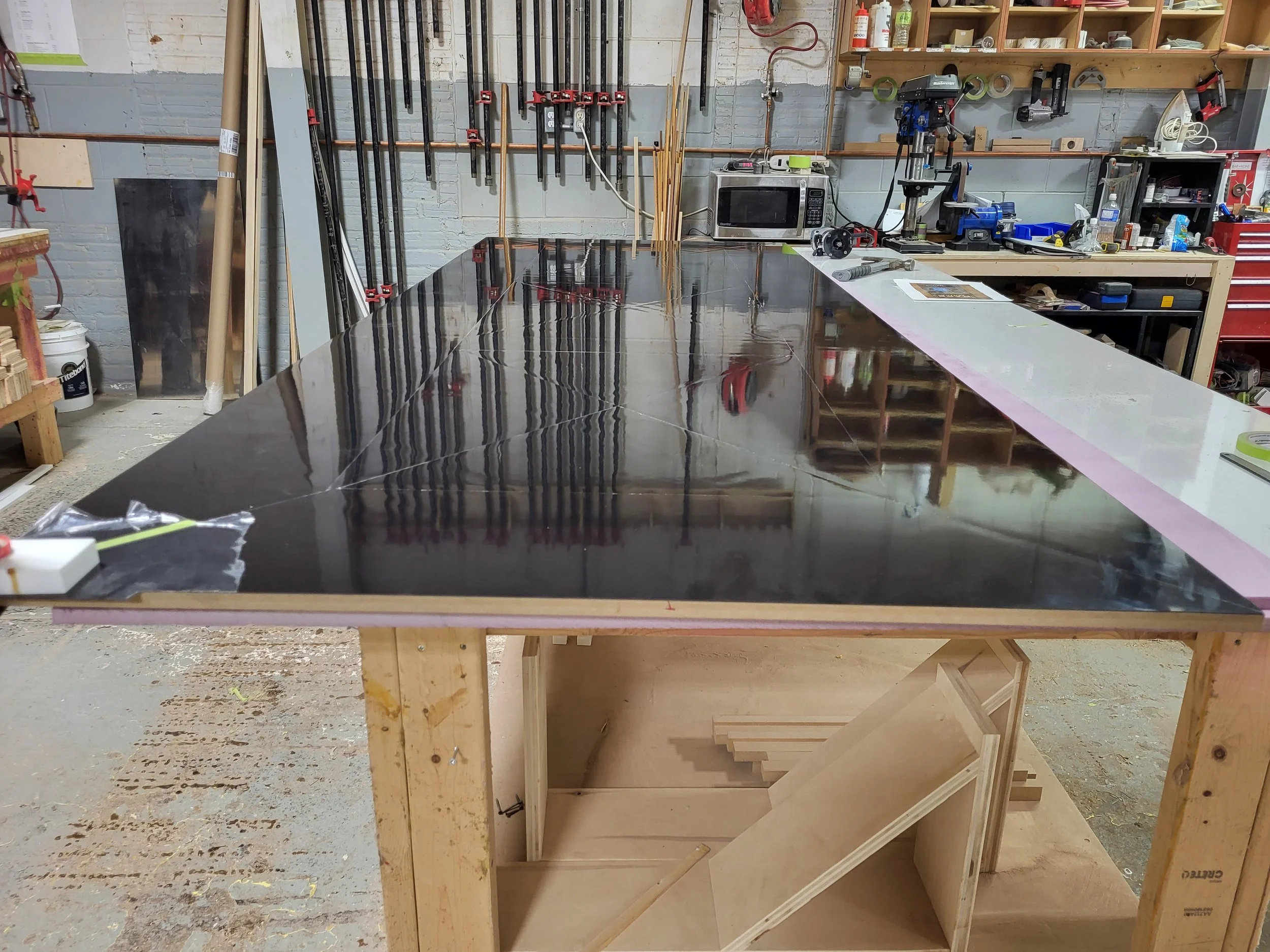

Final product, In the shop before being shipped and hung on-site at the Medium Rare Lounge at Rare Bar.

Photo courtesy of Rare Bar

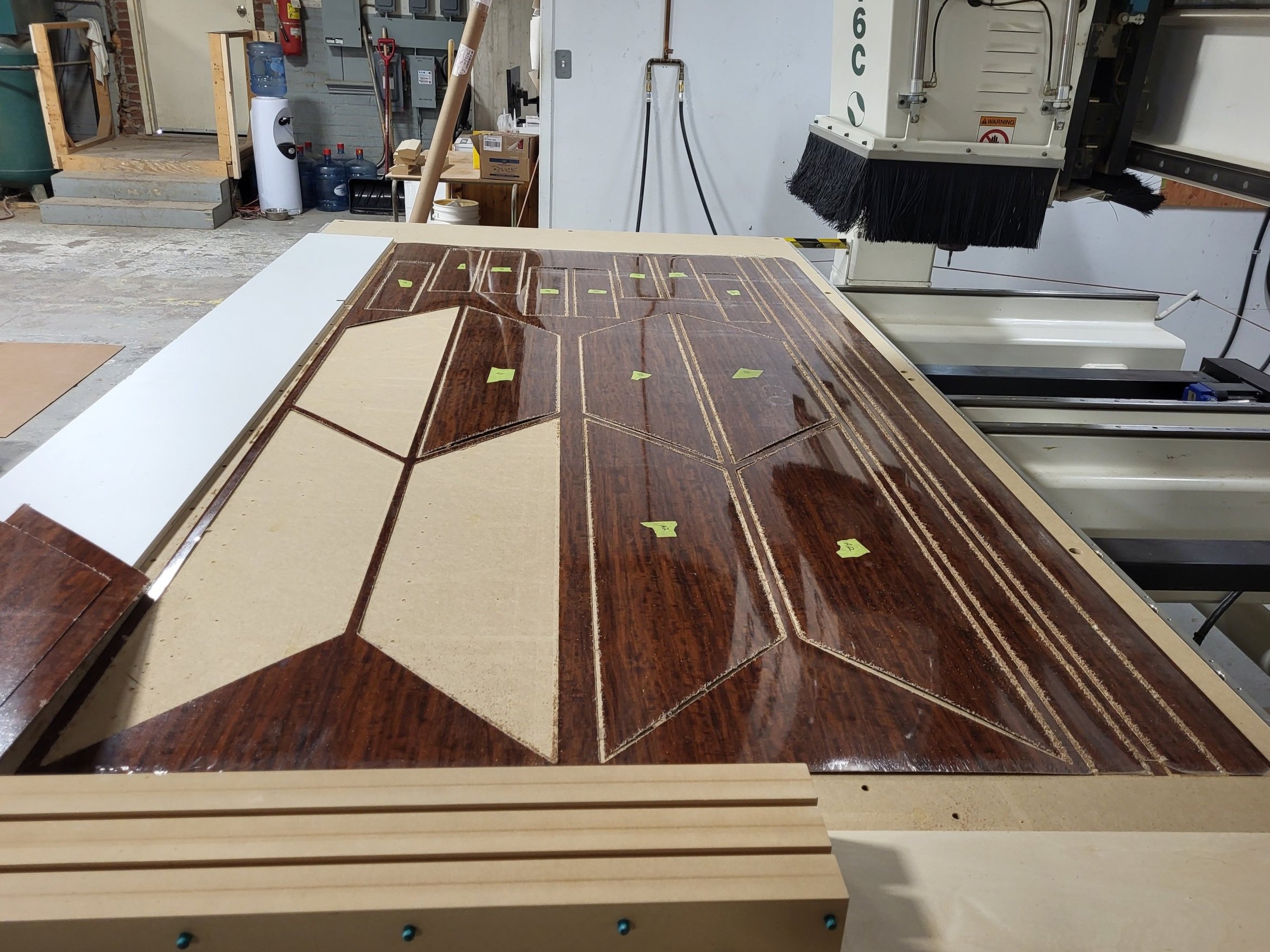

There were two sets of double doors with the same design in this project. One set of doors was 96” tall and the other set was 106 3/8” tall. Each door had two faces which needed machining. There was also three transoms of varying sizes to be manufactured as well.

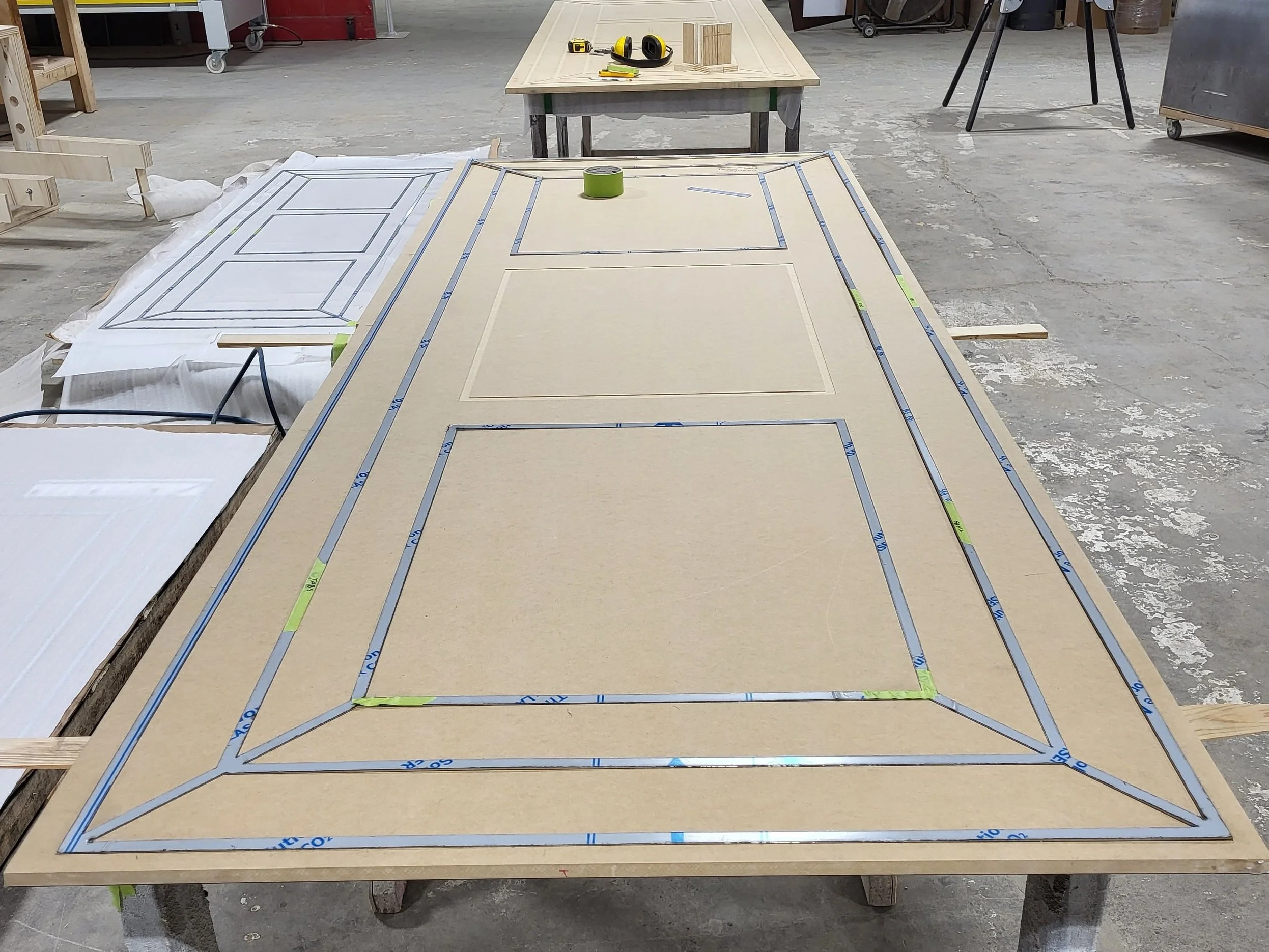

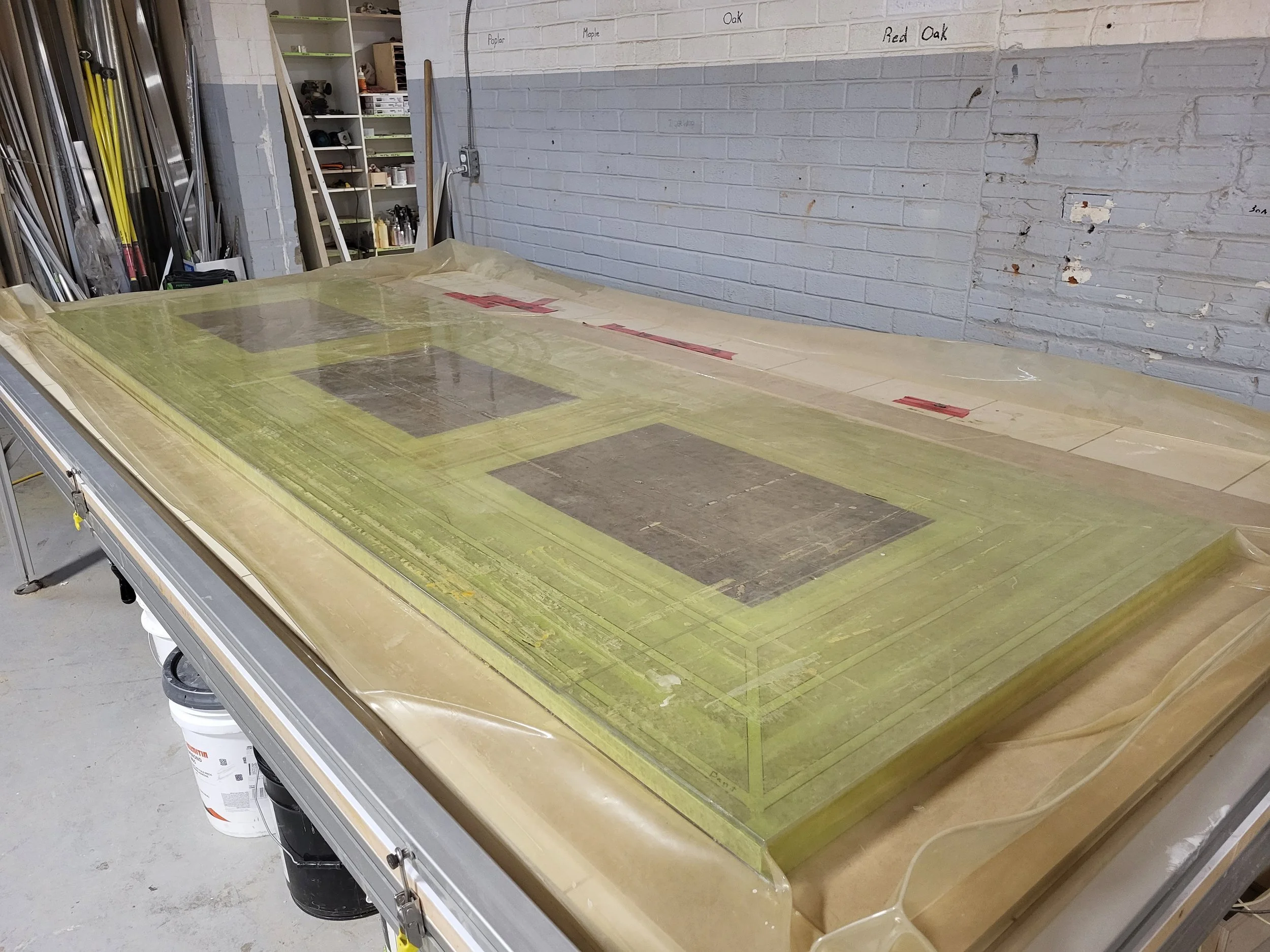

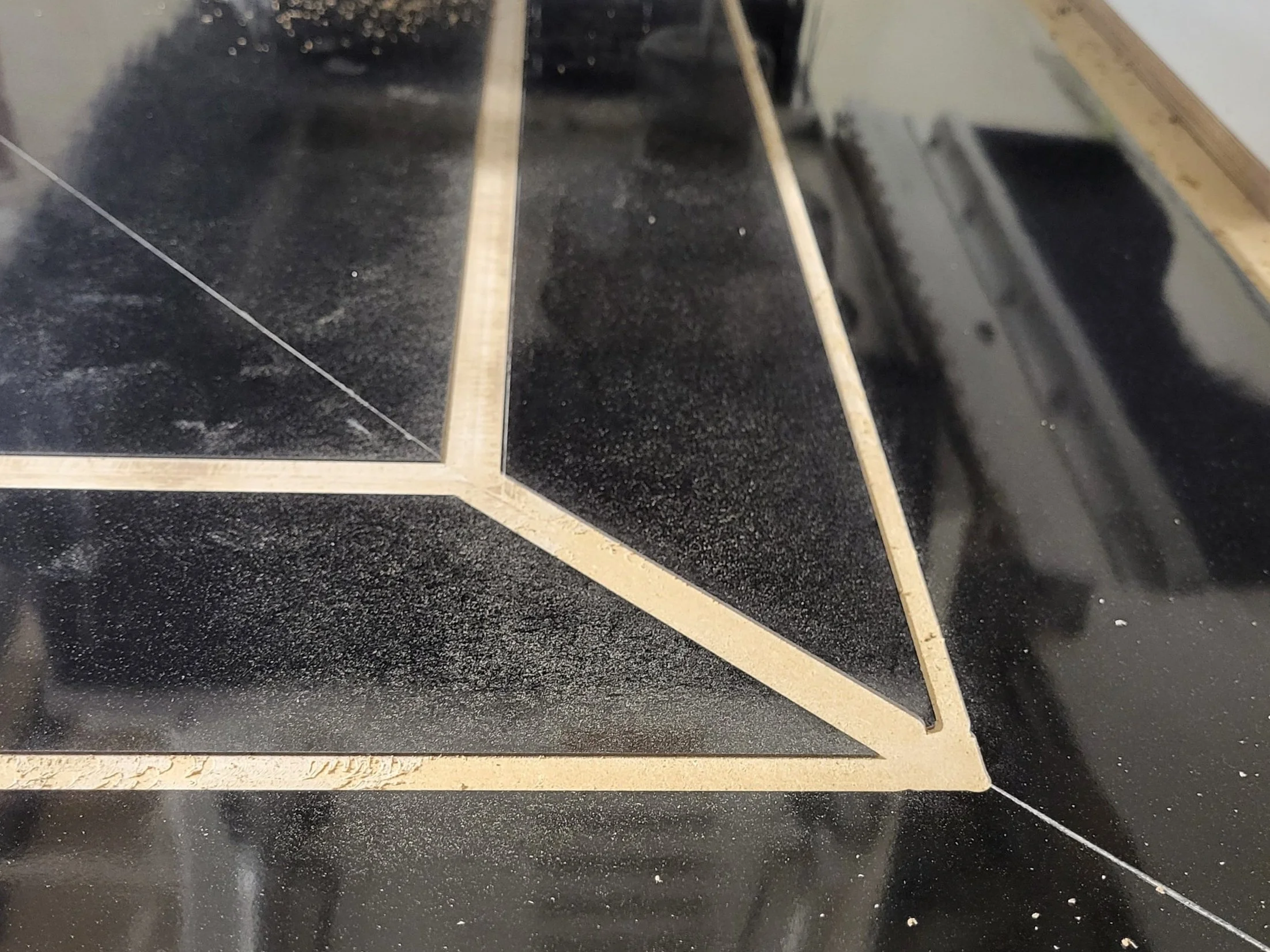

The doors were designed to have alternating grain direction of two different high-gloss plastic laminates. This required each section of laminate to be cut and pieced together before being laminated to the door. Once both faces of the doors were laminated, the channels for the metal inlay had to be machined in the exact desired location. I spent a lot of time running tests for these reasons.

Dealing with high-gloss laminate and polished stainless steel added a layer of difficulty to this job. Any scratches, dimples, loose seams, or other imperfections would catch the light and become visible.

Stainless Steel Inlay Process

Laminate Process